PICEA piezo-intelligent clamping system

Piezo Intelligent Clamping Entity for industrial Applications

Precision-controlled actuators

Intelligent system integration

Cyber-physical interaction

Energy-adaptive dynamics

Application-specific scalability

Our digital solution for intelligent and µ-precise machining of intricate workpieces. Discover unimagined possibilities for networked workpiece machining with impressive efficiency.

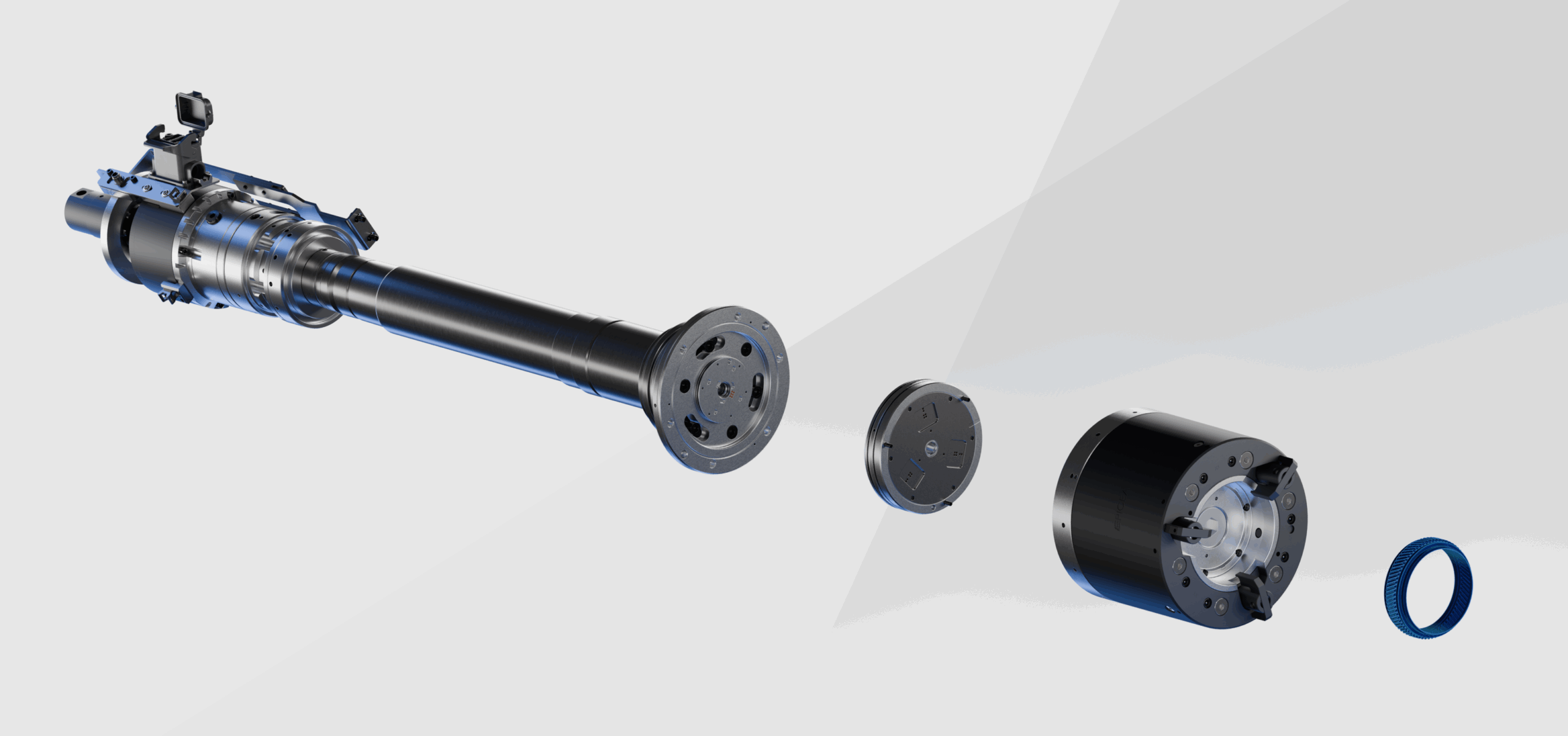

Piezo-based or on the basis of linear technology. Smart and adaptive.

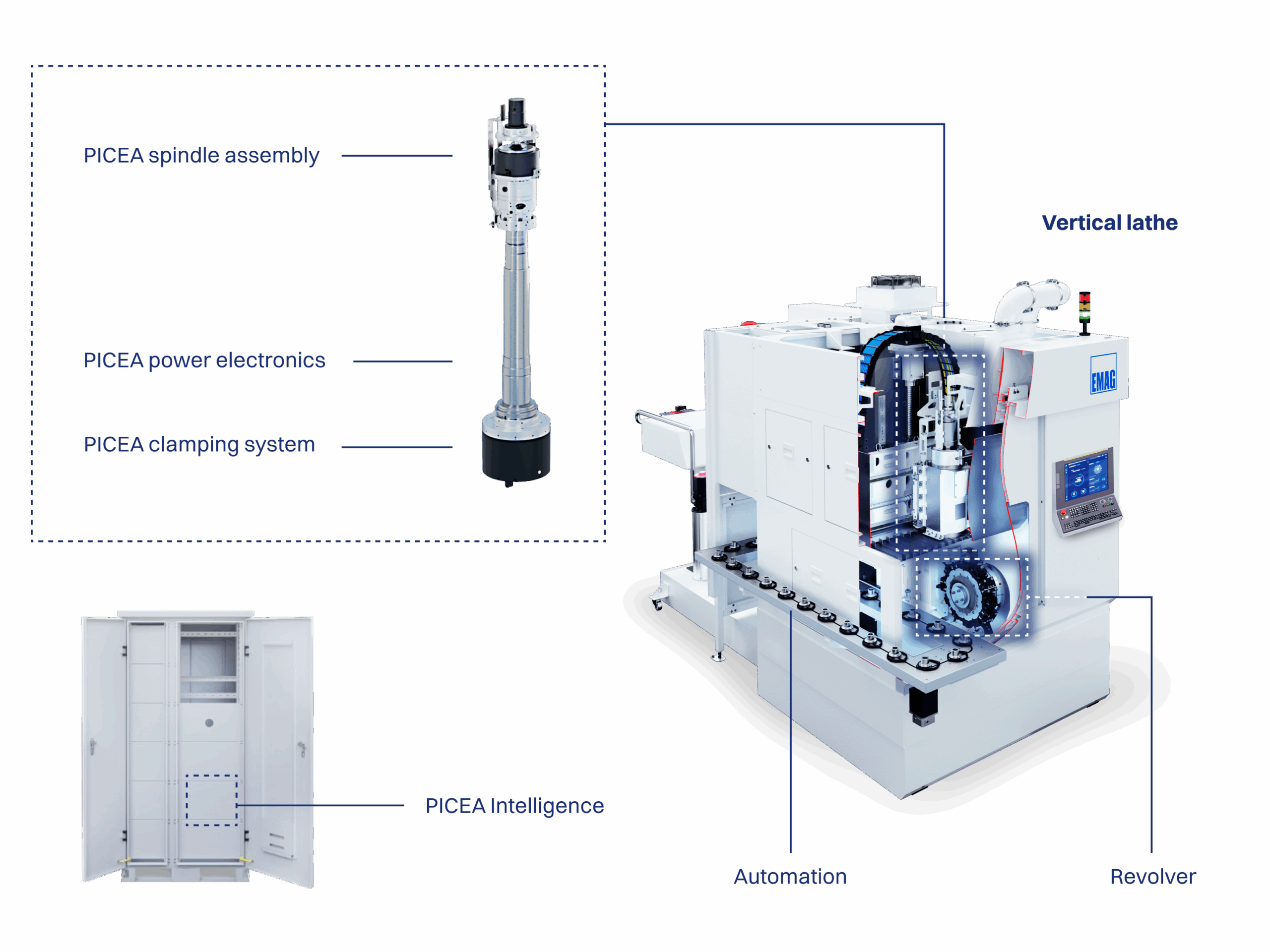

Digital clamping system, power electronics and power and data transmission

- Power supply & energy transfer

- Bidirectional data transfer

- Real-time control

- Robust electrical contact

- Piezoelectric centring function

- Sensors/actuators in the process adjustable

Features

- Integrated measurement before workpiece clamping or machining directly by the clamping system, e.g. on the pick-up station of the machine tool

- µ-precise electrically controllable and deformation-free electrical centring up to deliberate µ-precise deformation of workpieces

- Can be combined with classic pneumatic or hydraulic force clamping, such as an additional swiveling face clamping

- Deformation-free active or pulsating damping of machining forces and vibrations during machining

- Real-time monitoring of all process parameters during machining with smart big data and AI capabilities (all clamping and process parameters can be stored and retrieved on a part-by-part basis)

- Real-time calculation of actual machining parameters and proactive correction directly in the process

- Integrated STERMAN control unit PICEA Intelligence as a communication interface to conventional machine control

- Bidirectional real-time transmission of energy and data at 3,000 rpm between the clamping system and the PICEA Intelligence control unit

- Can be easily integrated into existing machines via a retrofit with simple connection to the machine control system via ProfiNET and ProfiBUS

Everything from a single partner.

For new machines as well as for conversion projects: We accompany you from the first idea and the initial technical concept through design, production and project management to commissioning and far beyond.

Turnkey for new machines or retrofit for the conversion of existing systems

PICEA can be implemented as original equipment on a new machine or adapted to an existing machine as part of a retrofit project. PICEA clamping technology, power electronics and spindle assembly are designed so that the technology can be easily integrated into a standard A6 DIN55026 / DIN55028 machine spindle.

The PICEA Intelligence control unit is added to the machine’s control cabinet. Communication between the machine controller and PICEA Intelligence is based on either PROFIBUS (Process Field Bus) or PROFINET (Process Field Network).

If required, PICEA Intelligence can transfer workpiece-based data on measurement, voltage and process bi-directionally in real time to higher-level host computers and actively intervene in processing strategies using AI or other calculation logic, for example.