We're not developing standards -

We're developing the future.

μ-THINKING ®. Great things always start in detail.

Production technology - made in the Black Forest.

Together, we create production technology for the industrial manufacturing of the future. We are one of the quality and technology leaders in special clamping technology and equip a large number of well-known and globally active companies with high-precision, efficient and smart solutions for their production. Our core competence lies in the design, development and production of clamping systems based on the individual workpiece geometry of our customers – i.e. whenever standards available on the market do not achieve the required accuracy or the desired machining processes are not easily possible.

We create solutions.

Customized clamping systems, fixtures and machines: whenever the standards available on the market do not achieve the required accuracy or the desired machining processes are not easily possible.

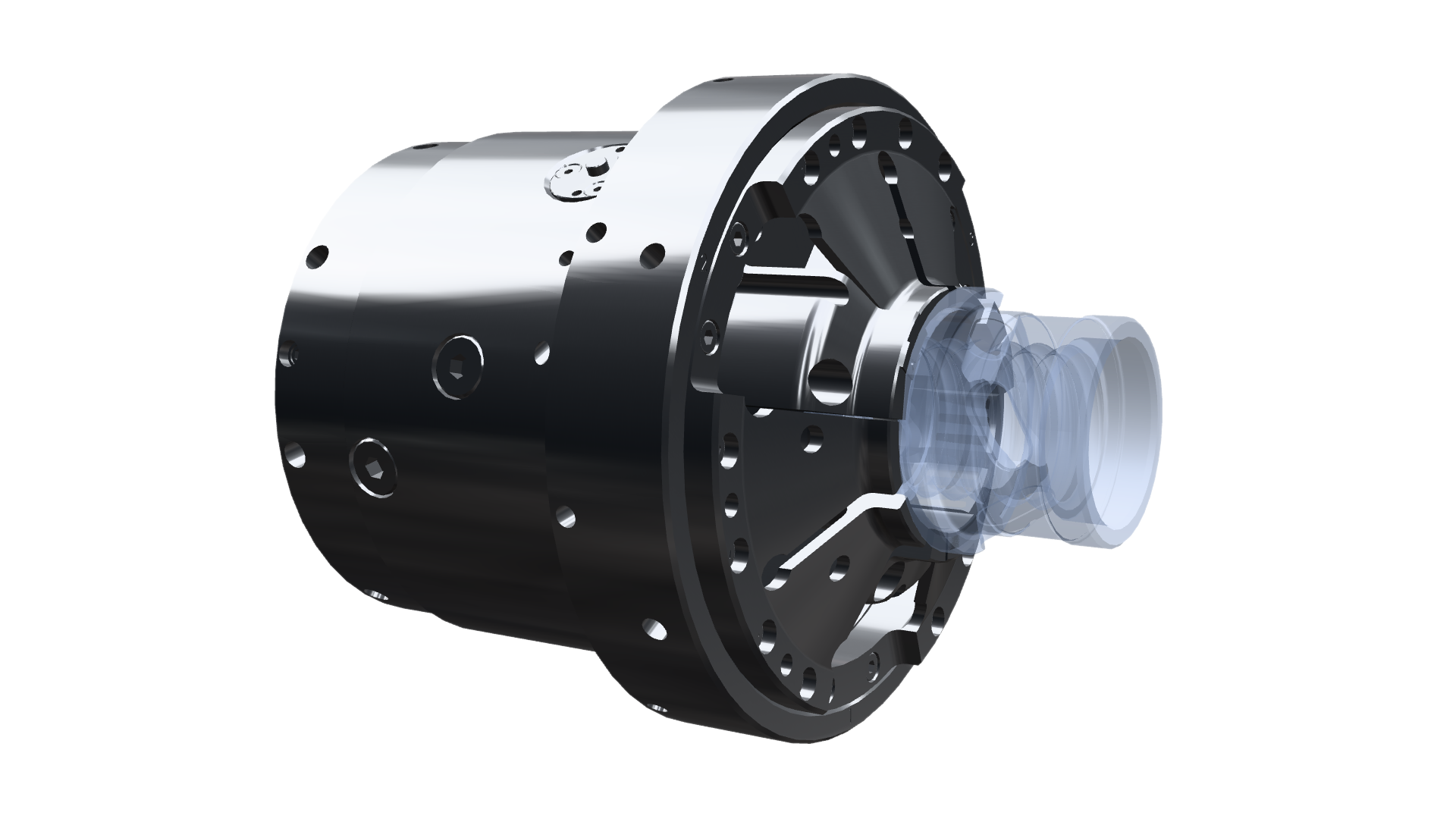

Spindle assemblies describe actuation units of clamping systems. They also supply additionally required media such as hydraulics, pneumatics or coolant. Our spindle assemblies usually consist of clamping cylinders, rotary distributors, drawbars with media feed-through and sensors. The customised design is always optimally adapted to the requirements of the clamping system, the machine spindle and the machining process.

Discover spindle assemblies made in Black Forest for yourself.

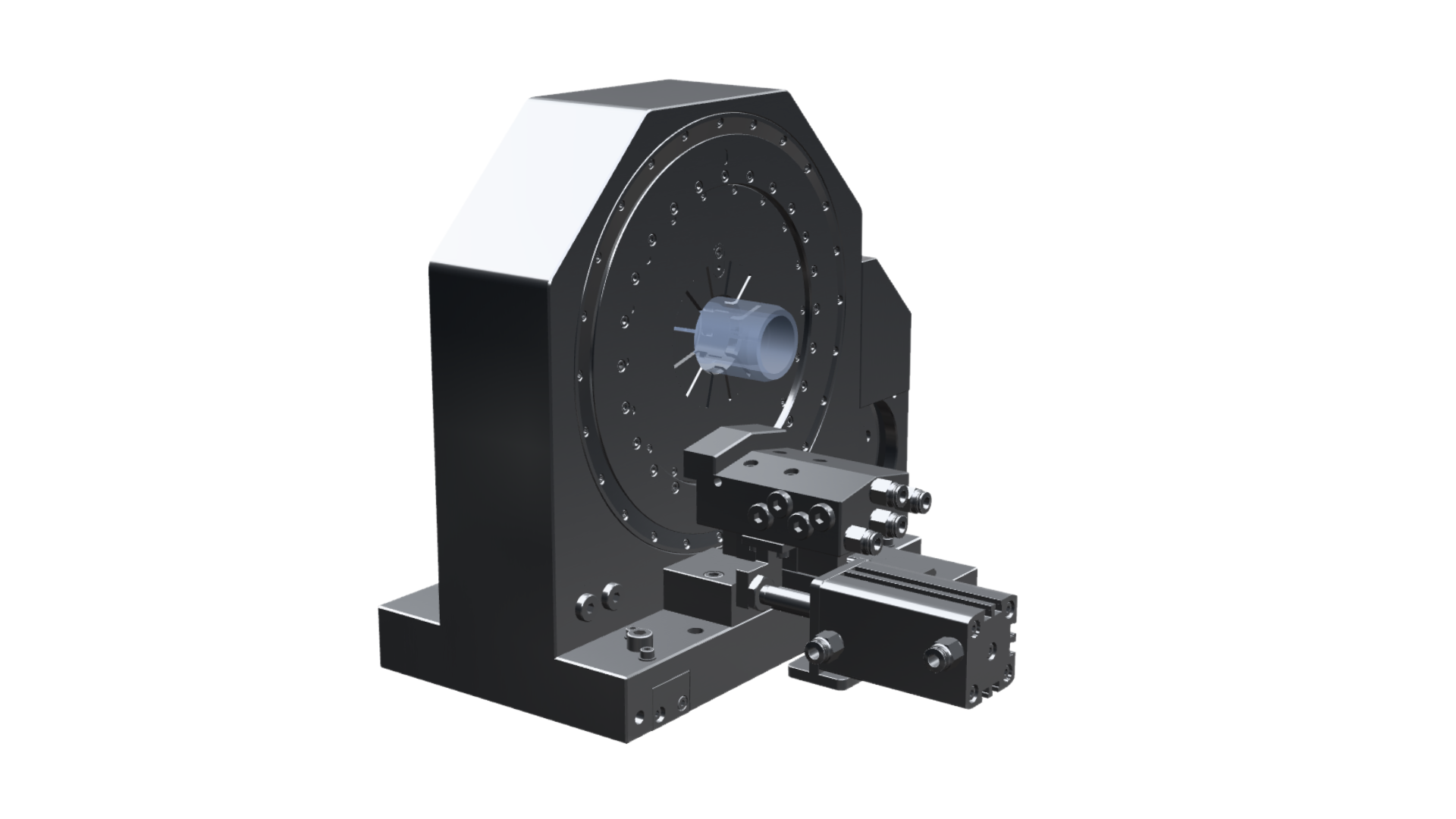

We design, develop and manufacture our special clamping systems customised to the individual geometry of your workpiece and the requirements of your machining process.

Discover clamping systems made in Black Forest for yourself.

The centrepiece of our fixtures and machines are µ-precise clamping systems. We realise flexible fixtures around the clamping system and can take over the entire mechanical engineering on request. As a system supplier, we take responsibility for the entire project and realise high-precision, smart and CE-compliant production systems.

Discover fixtures & mechanical engineering made in Black Forest for yourself.

Everything from a single partner.

For new machines as well as for conversion projects: We accompany you from the first idea and the initial technical concept through design, production and project management to commissioning and far beyond.

Made for your industry and application.

The demands placed on machining processes in industrial production are constantly increasing. We develop clamping systems, fixtures and machines that are perfectly matched to your workpiece. For precise machining, exact positioning, deformation-free clamping and high torque transmission.

MADE IN BLACK FOREST - for discerning customers all over the world.

μ-THINKING@Social-Media

#STERMAN – follow our team of inventors, quality and technology leaders.

Making a big impact with small actions.

Sustainability is not a trend, but an obligation towards the environment and future generations. At STERMAN, we have established sustainable thought patterns and processes from the outset and continue to develop them consistently. As a family business with deep roots in the region, we consider it our duty to act and operate accordingly.

MAKE A HIGH-END CAREER WITH US!

We are a team of inventors where you can achieve great things. Seize the opportunity. We offer exciting positions for experienced professionals, newcomers, trainees and students. We look forward to hearing from you.